Virginian Research

(From Railway Age Gazette, Vol. 54, No. 25, June 20, 1913, pp. 1557-59.)

Tunnel Lining On The Virginian Railway.

Details of the Methods Used In Placing Concrete Linings In Eighteen Main-Line Tunnels without Interruption to Traffic.

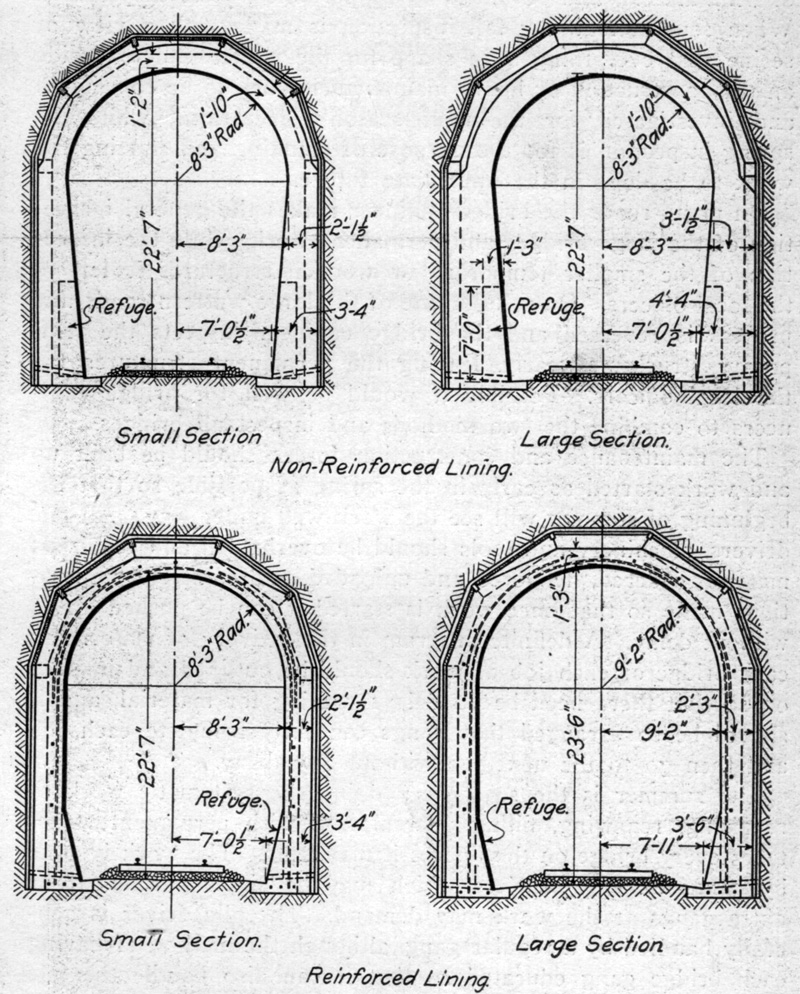

The Virginian Railway let a contract about two years ago for the lining of 18 tunnels on the upper portion of the road. Three are now completed, work is under way on two more and the others will be undertaken at a rate which it is expected will finish this contract in about three years more. Most of these tunnels were timber lined when they were built, but some, which are located in hard material, were left unlined. A rather serious cave-in of one of these tunnels showed that the unlined ones are not as safe as could be desired, and it was therefore decided to undertake the lining of all tunnels about the safety of which there was any question. The concrete linings which are being placed are built to four standard plans, for large and small sections, and with and without reinforcement, as shown in the accompanying cross sections. Work is being done without interruption to traffic, and on account of the size of the contract the contractor and the company’s engineers have together developed a system for handling the work which is proving very efficient.

The details of the work at the tunnel about two miles east of Princeton, W. Va., will serve to illustrate the methods used on all of these jobs. This tunnel is 1,700 ft. long, the material being comparatively soft stone, which is loose in many places and is rather wet. On account of the character of the material the reinforced concrete lining is being used, and on account of the size of the bore the large section is required. This section is 23 ft. 6 in. high from sub-grade to invert and 18 ft. 4 in. wide, the walls being vertical from the springing line down to a line 5 ft. 7 in. above sub-grade. From that line down they are battered to give a footing 3 ft. 6 in. wide for the support of the wall. The minimum thickness of the lining inside the old timber rings is 15 in., the walls being 2 ft. 3 in. thick from the face of the old lagging. An 18 in. gutter is provided inside the footing. The reinforcement in the footing consists of three 3/4-in. rods laid longitudinally, which are used only in yielding material. The reinforcement in the side wall consists of vertical 3/4-in. rods spaced from 2 to 3 ft. apart, as required by the character of the material. These rods are long enough to extend about 4 ft. above the springing line and are bent to form a bond with rods in the arch ring. The ring reinforcement also consists of 3/4-in. rods placed in three pieces; the lower pieces coming down to the springing line overlapping the wall rods by 4 ft. and the middle rods, or key reinforcement, overlapping the upper ends of the other rods 3 ft. In addition to this reinforcement there are 19 3/4-in. rods placed horizontally, as shown in the accompanying cross section.

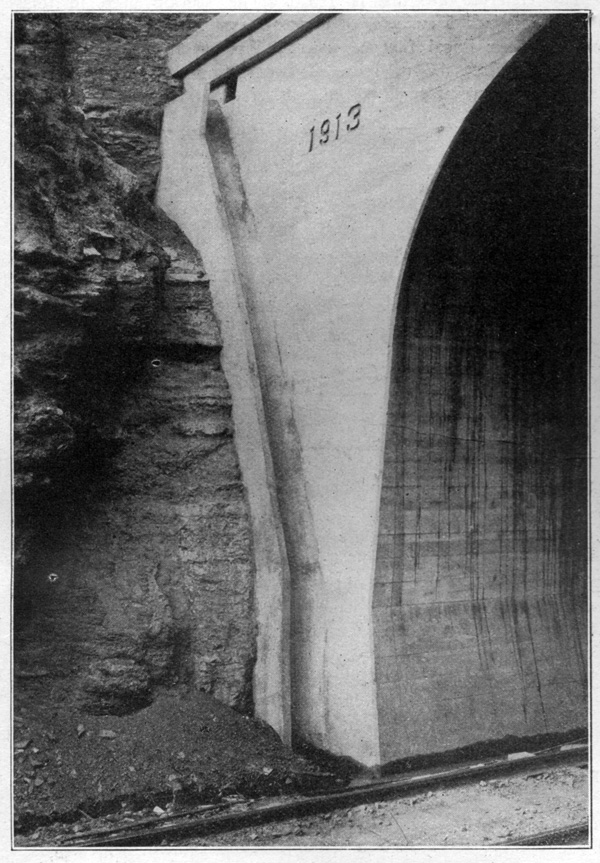

The concrete mixture is 1:3:6. The section used in this tunnel required 5 cu. yds. of concrete and 100 lbs. of reinforcing rods per lineal foot of tunnel. The small section unreinforced requires 4.7 cu. yds, of concrete per lineal foot, the small section reinforced, 4.4 cu. yds of concrete and 100 lbs. of steel, and the large section without reinforcement, 6.4 cu. yds. of concrete. Refuge niches 3 ft. wide are provided at intervals of 200 ft. on each side, staggered. Weep holes in the side walls just above the gutters are spaced a maximum of 50 ft. center to center, 3 in. galvanized iron pipe being used for this purpose. In particularly wet places, holes were bored through the old lagging and 4 in. drain tiles were placed over these holes to carry the water to the weep holes. Where necessary, these drains are provided at intervals as close as 10 ft. In some cases wooden boxes were substituted for the drain tiles, these boxes being 3 in. square inside and framed of 1 in. material, unfinished. The back of the portal is sloped to drain all surface water to a concrete basin built into the back of the portal wall at one extreme end, from which the water is carried through a hole in the parapet wall and down a concrete drain to the roadway ditch. The construction of this drain is clearly shown in one of the accompanying photographs.

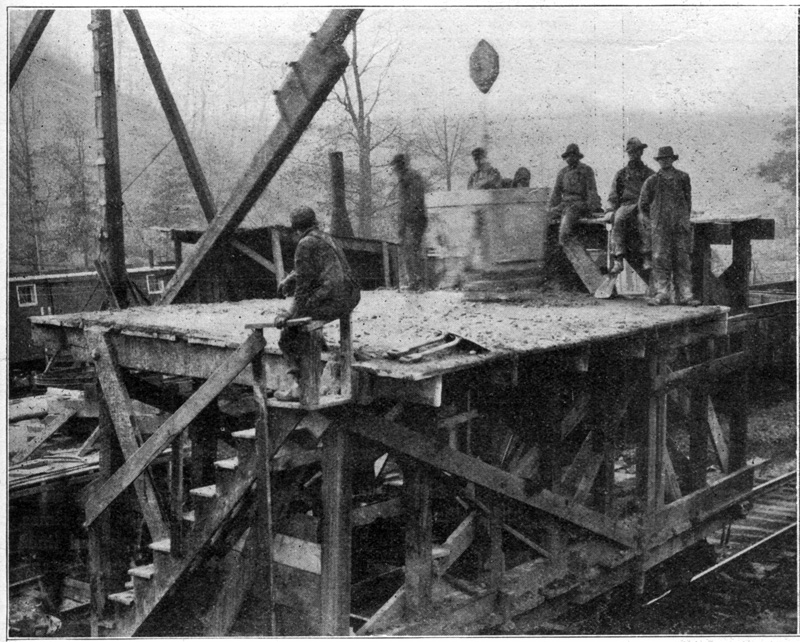

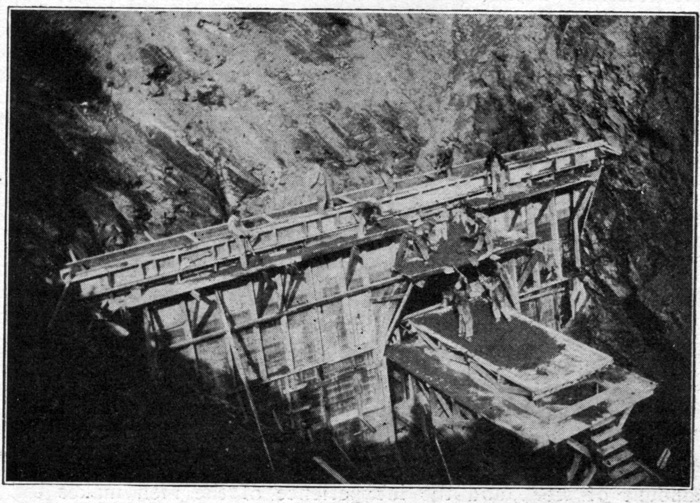

Concrete Car with Two High Levels for Shoveling Into Upper Portion of Forms.

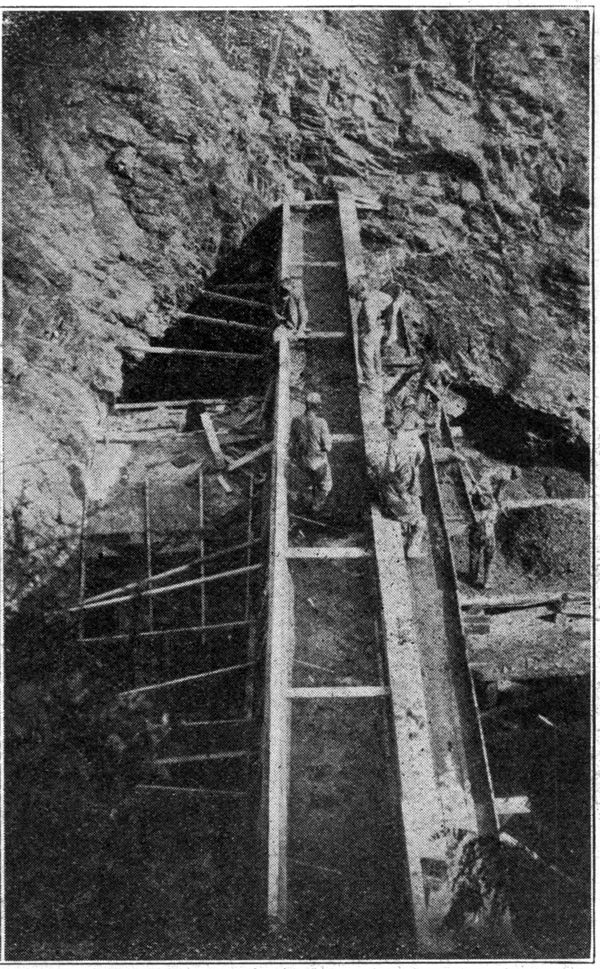

Placing Concrete In Parapet Wall at Portal by Shoveling Twice.

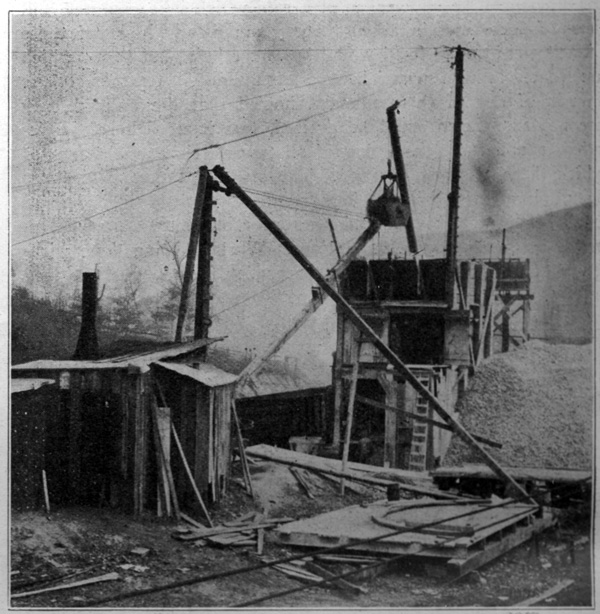

The concrete plant for handling this work is located at the end of the east approach cut, about 300 yds. from the portal. The sand and stone for concrete are brought in in coal cars, the stone being secured from the Sinking Creek quarry about 35 miles away, and the sand from Norfolk. Va. This material is unloaded by a 65 ft. derrick and one yard clam-shell bucket into storage piles having a capacity of 250 yds. of sand and 350 yds. of stone. The cement house holds 2,000 bbls. A water tank with a capacity of 3,000 gal. supplies water by gravity to the mixer and the dinky engine which operates the concrete car in the tunnel. In order to carry on the work in cold weather, a small vertical boiler near the mixer is used to heat the mixing water and steam pipes are laid in the sand and stone storage piles to heat these materials. The water is heated whenever the temperature falls as low as 32 deg, and the sand and stone when the temperature reaches 28.

Concrete Drain for Carrying Water from Back of Parapet Wall Down to Roadway Ditch.

The unloading derrick which takes the material from cars is used to place the sand and stone from the storage piles into hoppers over the mixture plant. These hoppers have a capacity of 25 yds. of stone and 20 yds. of sand. From these bins the material is dropped into a steel proportioning hopper directly over the mixer. Two men are stationed on the platform above the mixer to proportion the materials, being guided by lines ruled on the inside of the steel hopper so placed as to give the exact quantities of the aggregate needed to secure a 1:3:6 mixture. Each mix is proportioned on the basis of two sacks of cement. The cement is trucked out from the storage house and loaded on a steel skip which is set up on the platform in front of the mixing hopper by a second derrick which is used to handle the concrete buckets. From this skip the men in charge of the proportioning of the material take their bags of cement. The half yard Smith mixer dumps into 1 yd. buckets, two batches being dumped into each bucket and two buckets being filled during the interval that is required for the train to run into the tunnel and place the concrete. When the train returns to the mixing plant the derrick swings these two buckets of concrete that have been loaded over the cars and they are dumped on the shoveling platforms.

Concrete Mixing Plant, Material Hoppera at Top, ProportionIng Platform Below, Mixer at Bottom.

To provide electric power for lights in the tunnel and in the camp, a generating plant is installed which has a 14 k. w. generator furnishing 112 volt d. c. current. The generator is driven by a 20 h. p. engine, belt connected, which receives steam from the 40 h. p. boiler that serves both the light plant and the pumping plant.

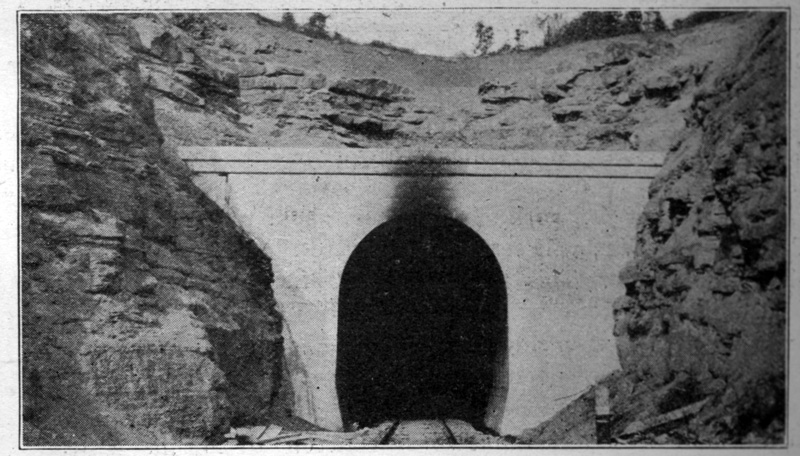

Portal of the Tunnel Near Princeton, W. Va.

The forms are built of long leaf pine dressed on all four sides. By careful handling this form lumber is used four or five times. All forms are framed in place, the posts being set up and lined after which the lagging is put in as required. The waling strips at the top of the battered section of the side wall and the wall plates at the springing line are bolted back to the old timber lining, the waling strip at the top of the footing being wired. The concrete is placed in sections 48 ft. long. The footings are first laid, then the side walls are put in up to the springing line in a single operation. During the placing of these side walls the vertical reinforcing rods are held in place by nailing 2 in. by 4 in. scantlings longitudinally along the old timber rings a little above the springing line to which the tops of the rods can be wired. The longitudinal rods in the side wall are placed as the concrete is carried up. With the exception of the key, the arch ring is also placed in sections 48 ft. long by placing three or four boards and filling over these and then placing more until the entire ring is turned with the exception of the 3 ft. key section at the top. This key section is placed in 4 ft. lengths by shoveling back after the closing forms have been placed. About 2 in. of mortar is placed over the forms in the key section before the concrete is put in order to insure a neat cement finish. Expansion joints are provided at the end of each 48 ft. section and adjacent sections are firmly keyed together. Forms are never removed within 72 hours after placing the concrete. The use of corrugated tin for protecting the concrete from moisture is being tried in this tunnel. This tin is placed in sheets behind the side walls and above the arch ring before any concrete is placed and before the forms are completed. The sheets are bent around the old timber posts and arch rings so as to fit the old timber lining closely and allow the concrete to fill the entire space. Where necessary, holes are cut through the old timber lining in order to allow the water collecting above to flow down behind these tin sheets to reach the weep holes at the bottom of the wall.

Building the Portal.

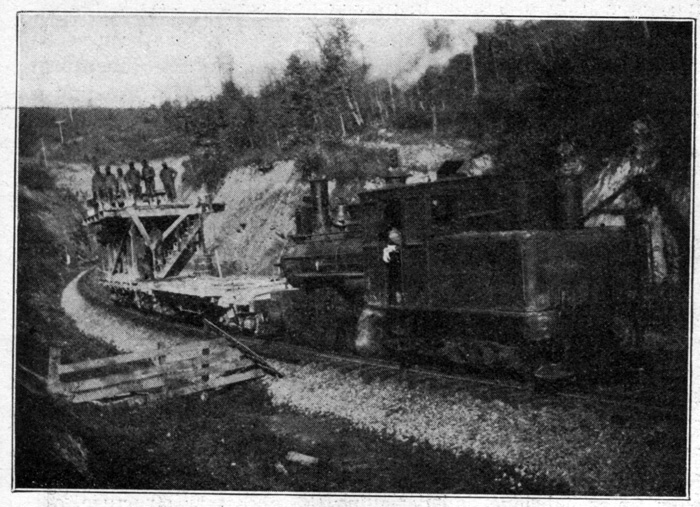

Train Used for Carrying Concrete from Mixing Plant to Tunnel.

The concrete is brought into the tunnel in 2 yd. batches on a train consisting of a dinky locomotive and two cars. One of these cars is an ordinary flat car from which the concrete in the footings and lower section can be placed, and the other is a flat car on which staging has been built to provide two higher floor levels from which the concrete can be shoveled into the upper portion of the side walls and the arch ring. The shoveling platforms are covered with sheet iron. Eight laborers are used on this car to shovel concrete into the forms and four men are kept in the tunnel to spade back the concrete from the face of the forms. The sequence of operations has been very carefully worked out so that no time is lost in the operation of this train. When the lower portion of the side wall is being placed it is possible to handle 125 yds. of concrete in a ten hour shift, although the delay occasioned by the difficulty in placing the upper portions of the arch ring, and particularly the key section, cut down the general average to 50 or 60 yds. per shift. In order to eliminate delay caused by the building of forms, concreting is carried on at two points in the tunnel alternately.

Cross Section of Completed Tunnel Linings.

As it is necessary to operate the concrete train over the main line, it is necessary to protect regular train movements very carefully. A man is placed at each end of the tunnel with telephone equipment connected to the despatching circuit, who warns the dinky of an approaching train and who gives clearance cards to all main line trains. No train is allowed to enter the tunnel without first stopping for this clearance. There are two regular passenger train movements a day, and from 5 to 12 freights. On account of the length of these freights and the slow speed at which they move and the occasional delay due to breakdowns in the tunnel, the total amount of delay from trains is a very considerable item.

This work is being handled under the supervision of H. Fernstrom, chief engineer, B. T. Elmore being division engineer in direct charge of the work in the field. The contract is being executed by W. W. Boxley & Co., Roanoke, Va.