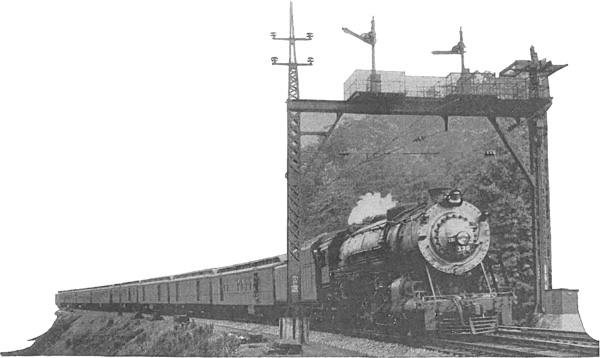

When Signals Were New

A Glimpse Into The History of The Railroad's Modern

Train Protection System Reveals Progressive Growth

By C. D. Potts, Chief Clerk, Signal Department, Roanoke

IN THE year 1900 a department of the Norfolk and Western Railway Company was organized which since has grown and accomplished much more than the average employee or citizen realizes. It is the Signal Department. Beginning with 12 men, including one draftsman, one foreman and gang, it has built up, on the Norfolk and Western, a signal system equal to that of any railroad in existence. Its 4,500 automatic signals, exclusive of approximately 350 crossing signals and 60 interlocking plants, are of three general types and embody the principles of every known method of efficient, informative communication employed by railways for the operation of trains by signal indication.

In the following paragraphs I shall endeavor to trace the history of this development from the date of the organization of the department to the present time.

The first signals were the manually controlled type used in connection with the movement of trains under what was called the “Telegraphic Block System.” They were located at telegraph stations and operated by telegraph operators who directed train movement. This was a very effective signal which warned the trainmen of any orders out for their train and also informed them of the condition of the block in advance. The rule was that operators would permit only one train at a time in the block. The train order information was given by hanging a red metal flag in the day time and a red lantern at night, directly under the arm which directed train movement. The movable signal arm was hand-operated by means of a lever.

The first automatic signals installed on the Norfolk and Western were two which were placed on the Scioto Division, in 1898, they being the Hall, banjo type, and battery operated. The westbound signal was put at the west end of Kenova passing siding, about 500 feet west of the passenger station and on the Kenova Bridge. The eastbound signal was at the east end of North Kenova passing siding, a short distance west of the Ohio River Bridge in Ohio.

These signals did not remain in service long because of their inefficient operation. They were soon retired and not replaced. In the fall of 1904 three style “B,” one-arm, two-position, automatic signals were installed in the vicinity of Watts water tank, between Radnor and Dunlow, on the Old or 12-Pole Line between Naugatuck and Kenova. At that time this line between these points was our only single track line handling traffic in both directions, the Big Sandy Line not having been constructed. These automatic signals were installed to prevent collisions which had been occurring in the vicinity of Watts. They were of the one-arm style “B” type as used today, having two indications, “Stop” and “Proceed.” No indication as to the condition of the second block in advance was given by this type of signal. An automatic signal operated by compressed gas was installed to protect the movement of trains over Bridges 7 and 8, on the Norfolk Division, but did not prove successful. These signals were soon replaced with motor operated signals. These first signals were installed before the department was formed and all work was done by the Union Switch and Signal Company under contract.

On March 1,1900, D. W. Richards, who had formerly been connected with the Union Switch and Signal Company, was appointed signal engineer. He had a clerk, a gang and an inspector and had the task before him of installing signals over the whole system. His office, consisting of one room, was located in the old passenger station in Roanoke until about two months before the building was torn down to clear the way for the one that now stands. He moved into the Gale Building, now known as the Lindbergh Hotel, and remained there about a year when he was given offices in the new annex to the General Office Building. Because of fire in 1909, Mr. Richards was obliged to seek quarters elsewhere and he moved to the third floor of the Huff Mill Building. This structure was erected in 1891 by W. P. Huff, who sold it to J. B. Andrews and F. B. Thomas, who, in turn, sold it to the Norfolk and Western in April, 1905. Eight months later the Salvage Warehouse was placed there. Mr. Richards and W. C. Walstrum, superintendent telegraph at that time, stored their heavy material there also. The basement of the General Office Building was used by the Signal Department for storing lighter material. In May, 1909, room was made on the second floor of the Huff Mill Building for an office and a drafting room. Partitions were put up and several adjustments made.

MEANWHILE, automatic signals and interlocking plants were being installed rapidly, construction forces having been increased to seven gangs. Automatic block signals were installed between Blake and Oakvale, near Bluefield, in 1905. These were style “B”, two-arm home and distant type, semaphore signals, the top arm indicating whether the first block in advance was occupied and the lower arm giving the same information as to the second block ahead, thereby providing increased safety, and speeding up the train movement. These signals were operated by 10 volts direct current, the source of which power was primary batteries. Oil lights shining through red, yellow, or green glass provided the necessary night indication. The daylight indications were displayed by the positions of the semaphore arms.

The work of installing automatic signals was pushed forward until in 1910 there was automatic block protection over 122 miles of double track. In that year the style “S” signal came into use. It was also a semaphore signal, but it had only one arm which operated in three positions, horizontal, diagonal and vertical according to the condition of the first and second block in advance. Power was supplied for the operation of these signals by a storage battery, these being charged from power houses located approximately 30 miles apart. Today power for signal and interlocking operation is obtained from a 4400-volt three-phase transmission line. This voltage is reduced at signal locations by means of a transformer.

In most instances the energy at this reduced voltage operates all of the signal apparatus, while at other locations this reduced alternating current voltage is changed from alternating current to direct current by means of rectifiers for charging storage batteries used for the operation of these signals. When storage batteries alone were used, the signals were wired for “approach lighting,” this being the scheme whereby a train approaching a signal automatically caused the light indications to be displayed until the entire train had passed the signal. Then the light was automatically extinguished. This scheme was used for the conservation of power.

In July, 1911, an alternating current signal was introduced. This was the one-arm, three-position, upper quadrant signal, but instead of the current having to be supplied through a rectifier and storage battery, only a transformer was necessary. The signal operated directly off the high tension transmission line, through the line transformer.

During this time Huff Mill was being changed to provide more office room. All signal stores were kept there and shelves, bins and facilities for handling materials were being improved. In 1914 the signal supplies at Huff Mill were taken over by the general storekeeper, but Mr. Frownfelter, “Uncle Johnny,” remained as signal storekeeper. He was retired in 1917. About this time the United States entered the World War and L. W. Scatchard, formerly assistant storekeeper, who had taken “Uncle Johnny’s” position, entered the service of his country. C. L. Callahan, then gang foreman, assumed the duties of shipping material from the “Old Hoss.” When Mr. Scatchard returned in 1919 an addition was made to the department which has been and is of tremendous value. The repair shop, with Mr. Callahan as foreman, was opened. Prior to this development all repair work was done by the Union Switch and Signal Company, but the excessive cost, as well as inconvenience and delays, necessitated a local shop. This shop occupied a room 12 by 25 feet which was gradually enlarged until now it consists of a room 40 by 50 feet and several smaller rooms. It is equipped with a line shaft carring[sic] seven belts, a 35-ton press, a drill press having eight speeds, a cylinder borer, a lathe, several electric drills, the latest type of band saw, and a complete wood-working machine. The shop has an annex in the southwest corner of the building which houses the battery room. Every type of storage battery used in signal work on our road is repaired there. Also, lamps are renovated and signal blades and signal number plates repainted. Impedance bonds, a device used only on the electrification district between Bluefield and Iaeger for permitting propulsion current to pass around the insulated rail joints at the same time making them effective for signal operation, are also reconditioned.

Outside of the main shop there is a blacksmith shop in which all heavy forging and welding is done. Adjoining it is a small building called the “Bond House.” It is here that bond wires, those wires used at rail joints to complete the circuit of current, are reconditioned. They are sorted, straightened, cleaned and the bonding plugs are covered with a coating of lead. This effects a great saving because otherwise new bond wires would have to be purchased at a cost of approximately five times that of reconditioning the old ones.

In conjunction with the signal repair shops there is a motor car shop. Sheffield 40’s, 40-B’s, 41’s and 46’s. Casey Jones’, and Budas, amounting to about 150 a year, are sent in, dis-assembled, cleaned thoroughly, repaired, reassembled, given the running test, painted and shipped back. Carburetors, magnetos, hand-bonding drills, and bonding drills run by a small gasoline motor are repaired here also.

IN THE signal repair part of the shops, such material as switch motors, signal motors, switch circuit controllers, switch shunt boxes, wig-wag mechanisms, pneumatic switch movements, signal air buffers, signal poles, dwarf signal mechanisms, all models of line transformers, pole changing circuit controllers, resistance coils, slot coils, signal locks, and track transformers are restored for service.

The “relay room” was opened in the same year as the shop, but later it was moved upstairs. In this room every type of relay used for signal operation on the Norfolk and Western is repaired. This means that about 3,000 relays, including vane track relays, vane line relays, slow release relays, high vane relays, centrifugal relays, galvanometer relays, interlocking relays and direct current relays are sent to the shops for repairs and are taken apart, cleaned, painted and polished, assembled, recalibrated and tested. Relays are, by far, the most delicate and sensitive mechanisms used in signal work. Their balance must be perfect and after repairs have been made, they must meet all test requirements before they are put back in service.

It is interesting to note that a red ant can stop the Pocahontas, the fastest and heaviest time freight, or the Twentieth Century Limited, merely by getting between the contact points of the relay, thus interrupting the flow of electric current and causing the signal to go to “Stop.”

The storehouse occupies a large portion of the building also. The entire basement. and third floor are used for the storage of signal, telegraph, telephone and motor car material. Emergency material of all kinds is kept in stock ready to ship and the organization of the storehouse is so arranged that one hour service at any time is available. It has at one time served 27 gangs and 180 maintainers.

The installation of automatic signals from 1910 was gradual and steady until in 1925 an innovation was made which illustrates the aim of the railroad to be as modern in its facilities and equipment as possible. This was the installation of position light type signals and automatic train control between Shenandoah and Hagerstown, on the Shenandoah Division. These signals are equipped with lights instead of semaphore arms. These lights are so arranged that they can be lighted so as to display a horizontal row to indicate that the block is occupied or that a hazardous condition exists; a 45-degree or diagonal position to indicate that the immediate block is unoccupied and the train can proceed, expecting to find the signal in advance in the stop position; or a vertical position indicating that two blocks ahead are clear and the train may proceed at normal speed. Position light signals and train control have since been installed between Roanoke and Shenandoah. Since the installation of position light signals and train control on the Shenandoah Division, position light signals have been installed also between Portsmouth and Cincinnati, Roanoke and Winston-Salem and Bluefield and Norton. This last installation completed the equipping of the main line and some of the principal branch lines of the entire system with automatic signals.

The Signal Department also has, as one of its functions, the installation of interlocking plants at foreign road crossings and crossings wholly owned by the Norfolk and Western. At such installations all signals, switch connections, all wiring and machines, are installed, by the Signal Department.

Interlocking is defined by the Standard Code of the American Railway Association as, “An arrangement of switch, lock and signal appliances so inter-connected that their movement must succeed each other in a pre-determined order.” An interlocking plant is defined as, “An assemblage of switch, lock and signal appliances interlocked.” There are four types of plants in service on the system, designated as, Mechanical, electro-mechanical, electro-pneumatic, and electric. The oldest plant on record is that at Hagerstown Junction, which is mechanically operated. It was installed in 1883, was enlarged to accommodate additional tracks in 1903 and, was overhauled in 1930 by the Pennsylvania. Of the 60 interlocking plants in operation on the Norfolk and Western, 40 are wholly owned and 20 are jointly owned.

Highway crossing protection is also taken care of by this department. In the day of horse-drawn vehicles, adequate protection at highway crossings was afforded by placing conspicuous signs at the crossing, one sign generally sufficing for a single or double-track crossing, the lettering on the sign conforming with the ideas of various railroad officials, state laws or state authorities. It was required that the engine whistle be sounded at varying distances from the crossing--one-fourth mile being the most favored--the engine bell to ring until the train reached the crossing.

The speed of horse-drawn vehicles was such that to avoid arriving at the crossing at the same time as the train they had to be quite close in order to hear either the engine whistle or the bell when the train was one-fourth mile away. Further, the radius of travel of a horse-drawn vehicle was, except where people were touring the country, fairly short; the drivers knew the location of all the crossings and were familiar with the train service over each. For these reasons, accidents were infrequent. If any additional warning was required, crossing bells, and, in some cases, watchmen and gates, were provided.

With the advent of the automobile the entire situation changed. Drivers were, in many instances, unfamiliar with the local conditions. The speed of the automobile at times equaled the speed of the train. Noises incident to operation of the automobile, especially of trucks, prevented the drivers from hearing the engine whistle, engine bell, and also the highway crossing bell far enough distant to stop short of the crossing. Recommendations were made for more adequate protection until now we have an electrically-operated wig-wag signal equipped with an elaborate display of warning lights. The whole signal is set on a concrete base which is painted with black and white stripes. Danger is reduced to a minimum.

Gangs form an interesting feature of the department. There are usually 12 men, including the foreman, cook, signalmen, assistant signalmen, helpers and a blacksmith on the camp cars, and they are engaged in the installation of automatic signals, crossing signals and interlocking plants. They live in rough but clean maintenance of way cars and with radios and what-not keep in touch with the times just as people living at home. Their meals consist of good, healthful foodstuffs. The writer had the real pleasure of partaking of their evening meal and it consisted of a generous supply of the following: Potato cakes, sausage, hash, two kinds of beans, salad, hot rolls, cheese and crackers, two kinds of pie and coffee. They are visited frequently by signal inspectors who check and inspect the installation in progress and who report to the signal engineer. Since the early years of signal construction, gang conditions have changed considerably. The first camp cars were merely box cars with windows cut in the sides and wooden plank bunks nailed to the wall.

One of the most completely signaled sections of track to be found on any railroad is the district between Cloverdale and the end of double track at North Roanoke. This district was originally protected with automatic signals of the position light type, installed in 1926, and in the following year automatic train control circuits were superimposed on this automatic signal installation, and later in 1928 the end of double track and the signals governing train movements over it and also the signals at the south end of the passing siding at Cloverdale were put under the control of the dispatcher at Park Street by the use of dispatcher’s control circuits. This installation eliminates entirely the use of train orders in connection with the movement of trains between these two points, trains being governed by signal indication only.

It is interesting to note that on this district the protection furnished consists of automatic signals, automatic train control and dispatcher’s control, with the result that, in addition to safeguarding the train movement, it is also materially facilitated into and out of Roanoke Terminal.

In July, 1929, the east end of the running track, one mile east of Vickers, was interlocked with the westbound main track and the pull-in switch, which had been formerly operated by train crews, was put under the control of the operators in the interlocking cabin at Walton, about four miles west of the switch location. This installation cut out all train stops for trains taking siding at this point, and although the operators are four miles from the switch, all signal indications and necessary information for the safe operation of the trains is furnished them with the same degree of exactness as if the switch were located directly in front of the cabin. A similar installation was also made at Stonecoal, W. Va., and handled by the operators at Kermit interlocking.

One of the most important facts to be considered in relation to the Signal Department is that since its organization all signal work, including plans and engineering, has been done by company forces. All plans and circuit designs are drawn at Huff Mill and all installations are made by the construction forces. Material is ordered either direct from the manufacturer or from the storehouse and the work is done by Norfolk and Western employees. This tends to localize as well as to centralize the work.

Automatic Train Control, and all wayside equipment of train-controlled territory, such as relays, transformers, wire and cable, is installed by signal gangs. Also the designing of circuits and all other engineering work in connection with the wayside equipment of the train control was handled in the Signal Engineer’s office.

Monthly failure reports of train control operation are compiled. These reports are forwarded to the I. C. C. giving them all information.

Safety is the keynote of the entire organization. The signals must display the correct indication of the condition of the track in advance of a moving train because the safety of every man, woman and child on the passenger trains and every ounce of freight handled depends upon the efficient operation and observance of signals. Safety is the sole aim of everyone employed in Mr. Richards’ department and each must have always in his mind the fact that no compromise can be made where safety is involved. Such is the responsibility of the Signal Department.

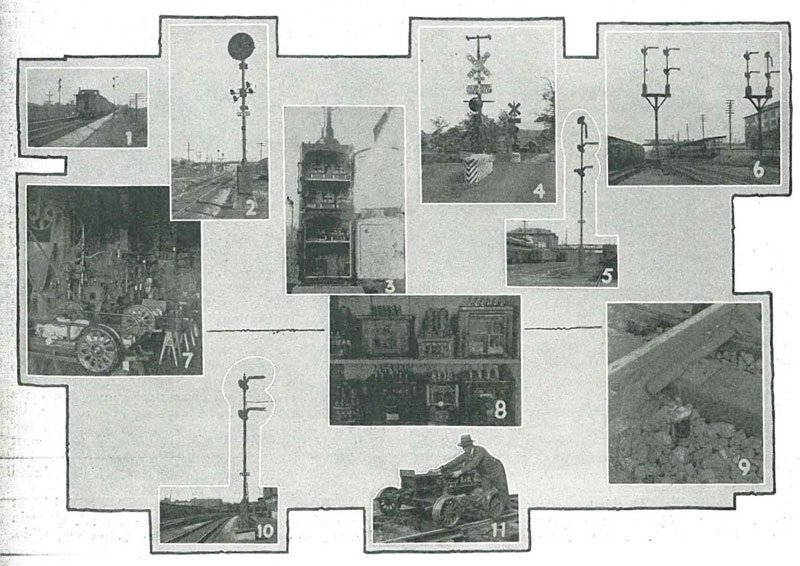

(1) Typical double location of two-position, lower quadrant automatic signal, near Salem.

(2) A two-arm position light interlocking signal.

(3) Interior of the case which contains the mechanism of a grade crossing signal.

(4) Wig-wag grade crossing signal.

(5) Eastbound automatic signal, at Commerce Street.

(6) Westbound automatic signals at Jefferson Street, Roanoke.

(7) A portion of the motor car repair shop in the Signal Department headquarters at Roanoke.

(8) Some of the various types of relays used in signalling on the Norfolk and Western.

(9) Typical connection for track wires.

(10) Westbound automatic signal, just east of Park Street, Roanoke.

(11) Signal maintainer, leaving headquarters for day’s work.

Norfolk & Western Magazine, Volume 10, No. 2, February, 1932, pp. 72-75